Drying Oven for Fabric Testing GT-D10

Product Introduction

Application: This Drying Oven is design for all kinds of textile’s perspiration resistance color fastness drying test, matching GT-D09 Perspiration Tester using. It also apply for high temperature heating & drying test for other products.

Standards:

Perspiration: GB/ T 3922, AATCC 15, ISO105-E04, JIS L 0848 Sea Water: GB/ T5714, ISO105-E02, AATCC107 Water: GB/ T5713, ISO105 E01, AATCC106 Saliva: GB/ T 18886

|

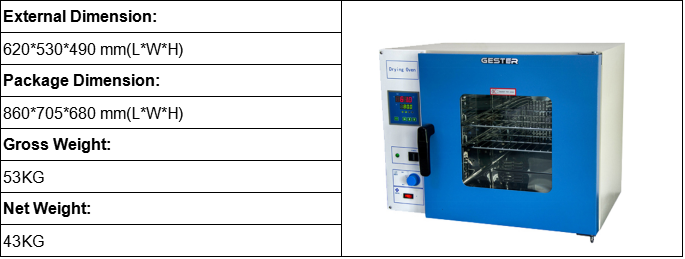

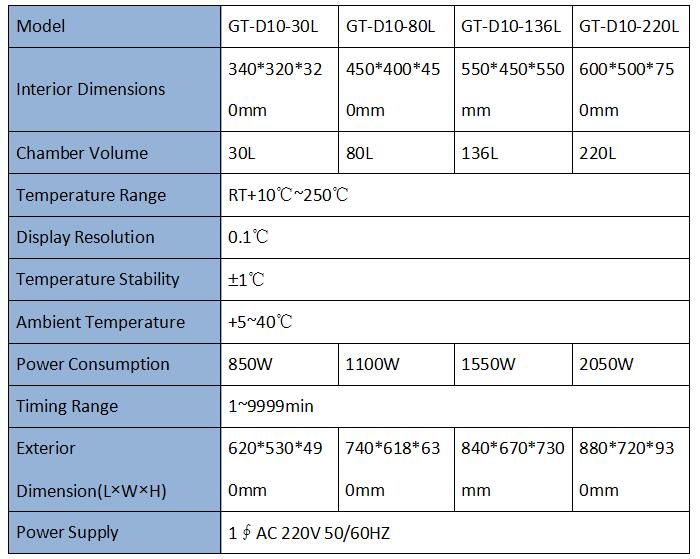

Dimensions

Feature

- Polished stainless-steel chamber.

- Latest PID controller.

- Uniform distribution of air temperature.

- Forced-air convection.

- Double Layer glass door, larger viewing window.

Key Specifications

Application Industry

All kinds of electroplating materials can be tested on the Drying Oven for Fabric Testing